¿Es seguro el tablero PET MDF?

2024-07-09 15:30

As a new type of material, PET MDF board has gradually been favored by consumers and manufacturers because of its environmental protection, durability and beauty. However, the safety of PET MDF board has also aroused widespread concern.

This article will discuss the composition, characteristics, application and safety of PET MDF board in detail to help consumers better understand this new material.

What is PET MDF board?

1. Definition of PET MDF board:

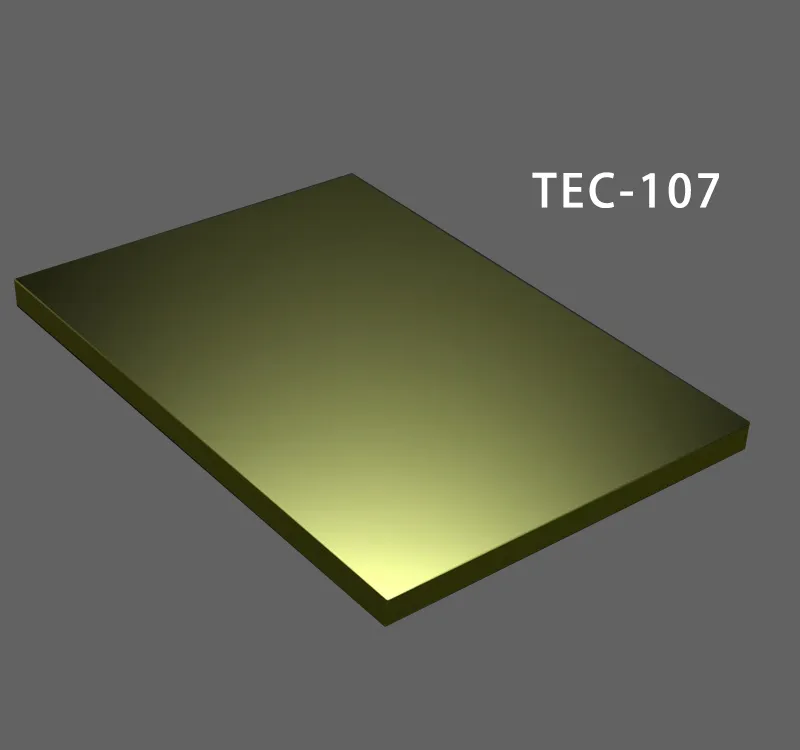

PET MDF board is a composite material with a layer of polyethylene terephthalate (PET) film on the surface of medium-density fiberboard (MDF board). MDF board is made of wood fiber and synthetic resin pressed under high temperature and high pressure, while PET film is an environmentally friendly plastic with excellent physical and chemical properties.

2. Production process of PET MDF board:

The production process of PET MDF board includes the following steps:

● Substrate production: First, produce MDF board that meets quality standards to ensure its smooth surface and uniform density.

● PET film processing: PET raw materials are made into PET film with uniform thickness and high transparency through extrusion, stretching and other processes.

●Laminating process: Cover the PET film on the surface of the MDF board, and through hot pressing, cooling and other processes, the film and the board are tightly combined to form an integrated PET MDF board.

Characteristics and application of PET MDF board

1. Characteristics of PET MDF board

● Environmental protection: PET material itself is a non-toxic, odorless and environmentally friendly plastic, and it can be recycled and reused. Compared with traditional surface painting or film laminating processes, the PET laminating process reduces the use and release of harmful substances.

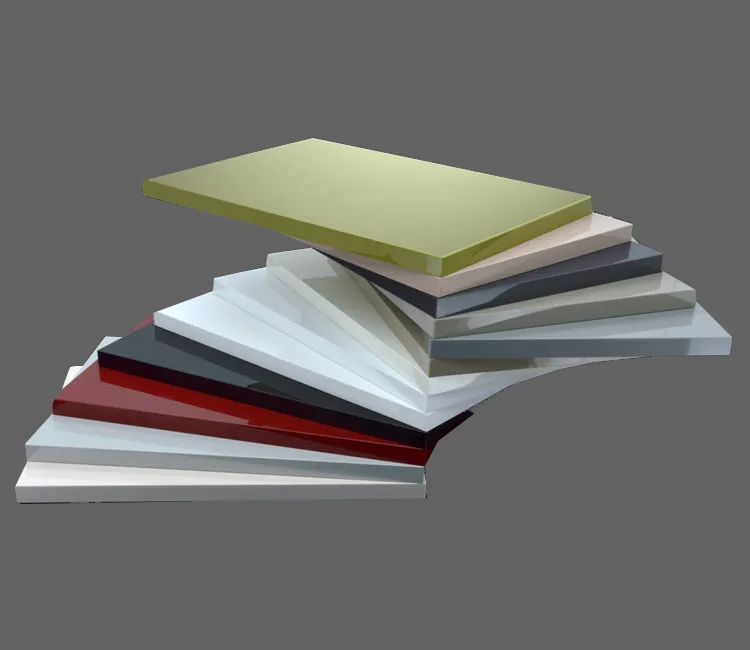

● Durability: PET film has excellent wear resistance, scratch resistance and corrosion resistance, which can effectively protect the substrate and extend the service life of the board.

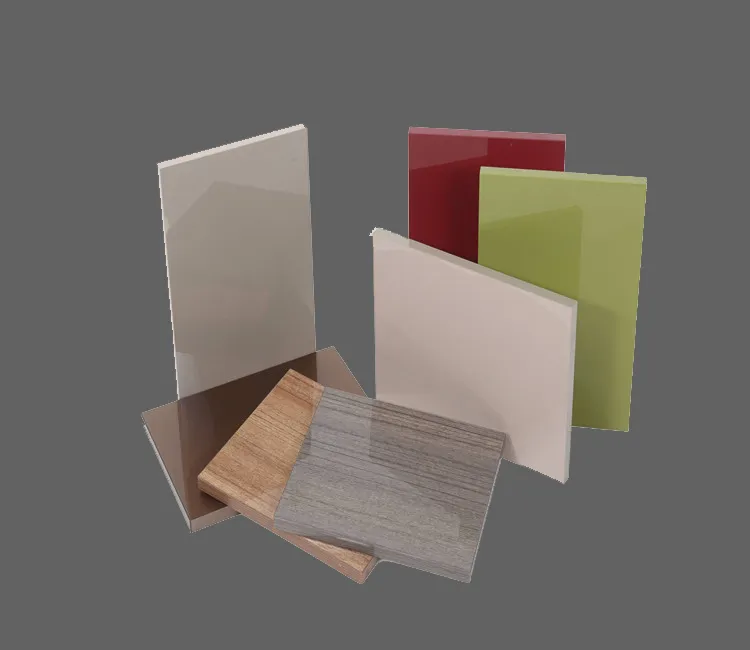

● Aesthetics: The surface of PET film is smooth and transparent, and various colors and patterns can be achieved through printing technology to enhance the decorative effect of the board.

● Easy to clean: The surface of PET MDF board is smooth, not easy to stain, and easy to clean and maintain daily.

2. Application of PET MDF board

PET MDF board is widely used in various home and commercial decoration scenes, including:

● Furniture manufacturing: used to make cabinets, wardrobes, bookshelves, tables and chairs and other furniture to enhance the appearance and durability of furniture.

●Indoor decoration: used for wall, ceiling, door panel and other decorations to meet the decoration needs of different styles.

●Commercial display: used for display cabinets, display racks, etc. in shopping malls, exhibitions and other places, which are both beautiful and practical.

Safety analysis of PET MDF board

1. Safety of raw materials

●PET film: PET materials are widely used in food packaging, beverage bottles and other fields, with good safety and environmental protection performance. In the production of PET MDF board, PET film as the surface layer can effectively isolate the influence of the external environment on the substrate and ensure the safety of the board.

●MDF substrate: The main components of MDF board are wood fiber and synthetic resin. High-quality MDF board will strictly control the use of harmful substances such as formaldehyde during the production process, and choose environmentally friendly resins with low formaldehyde or no formaldehyde.

2. Safety of production process

The production process of PET MDF board adopts hot pressing lamination process, which does not require the use of solvents or other harmful chemicals, avoiding the problem of harmful substance release that may exist in traditional painting process. Strict control of parameters such as temperature and pressure during the production process ensures the quality and safety of the board.

3. Safety during use

Environmental performance: PET MDF boards will not release harmful substances during use, meet environmental standards, and are harmless to human health. In particular, the formaldehyde emission of PET MDF boards tested and certified by authoritative organizations reaches the E0 or F★★★★ standard, ensuring the safety of the home environment.

●Durability: PET MDF boards have excellent wear resistance, scratch resistance, and corrosion resistance, and can effectively resist wear and chemical erosion in daily use, maintaining long-term beauty and functionality.

●Fireproof performance: PET MDF boards that have been specially treated also have certain fireproof properties, which can provide better safety protection in the event of a fire.

Expert opinions and future development trends

1. Expert opinions

Environmental protection and home material experts believe that PET MDF boards, as a new type of environmentally friendly material, have excellent physical properties and decorative effects, which make them have broad application prospects in the market. Experts suggest that consumers should give priority to authoritatively certified products when choosing PET MDF boards to ensure their environmental performance and quality safety.

2. Future development trends

●Technological innovation: With the continuous advancement of technology, the production process of PET MDF boards will be further optimized, and product quality and environmental performance will continue to improve.

●Product diversification: In the future, the product variety of PET MDF boards will be richer, and PET MDF boards of different thicknesses, colors and patterns will be launched one after another to meet the needs of different consumer groups.

●Market promotion: With the improvement of environmental awareness and the increase in consumer demand for high-quality home materials, the market share of PET MDF boards will gradually expand and become an important choice for home decoration and furniture manufacturing.

Consumer selection suggestions

1. Pay attention to environmental certification

When choosing PET MDF boards, consumers should pay attention to the environmental certification marks of the products, such as EPA, CARB, FSC, etc. Choose low-formaldehyde or formaldehyde-free products that have passed environmental certification to ensure the health and safety of the home environment.

2. Choose regular brands

Give priority to PET MDF board products produced by well-known brands and regular manufacturers. These brands usually have stricter quality control and higher product standards, and can provide better after-sales service and quality assurance.

3. Choose according to needs

Choose PET MDF board products with appropriate specifications and performance according to specific usage scenarios and needs. In high humidity or high wear environments, such as kitchens and bathrooms, it is recommended to choose PET MDF boards with better water resistance and wear resistance.

Conclusion

As an environmentally friendly, safe and beautiful new material, PET MDF board has broad application prospects in furniture manufacturing and interior decoration. Through reasonable selection and use, PET MDF board can bring higher decorative effects and usage experience to the home environment.